Note: Updated 24th Oct

Mercedes GP are rumoured to be running a novel front wing. This has been reported in the three major F1 magazines (AMuS, Auto sprint and Autosport). It seems the front wing uses the nose hole to blow a slot under the wing. Although this is a completely passive system (i.e. no moving parts or driver intervention), the fact that it alters aero performance at speed, has seen it dubbed as an F-duct Front Wing.

This solution was first heard of by Michael Schmidt of German magazine ‘Auto Motor und Sport’ (AMuS). Schmidt passed the tip off to Giorgio Piola who spent hours in the pitlane observing the Mercedes car and how mechanics handled the different wings. A task made additionally difficult, as he could not arouse suspicion by Mercedes and give away the fact he was researching the tip off.

He found only two noses had the nose-hole with the splitter and that these wings were only carried parallel to the ground when moved around the pitlane. The final piece of the jigsaw was when he saw a mechanic inspect the wing with his hand leading to understand the slot placement and this information allowed him to work out the system and draw it for the aforementioned magazines. Its remarkable such a tiny detail can be observed and goes to show the hard work that went into Piola exposing this innovation.

Description

AMuS article

Autosprint article

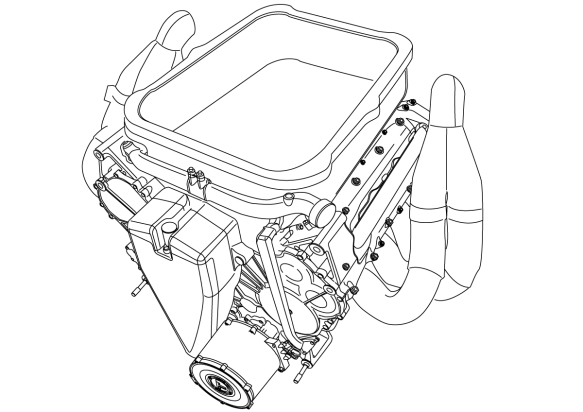

As described in the illustrations and texts, the wing assembly (including the nose) is as follows. The nose hole is used to pass air down through the front wing pylons into a slot on the underside of the wing. It appears that the slot has a wide span and is very narrow.

The nose hole feeds air through a duct into a slot under the front wing

This design is somewhat similar to Mercedes early 2010 F-duct rear wing, which was passive. The driver didn’t have a control duct, as with the McLaren system. Instead the ductwork would only blow with enough force to stall the rear wing at a certain airspeed. Tricky to design and tune, this system worked well for Mercedes last year. Its not improbably that just such a system could be made to work on the front wing.

Aiding downforce or stalling the wing?

Typically slots in the wing are for two purposes; aiding or stalling the flow over the wings surface. How the slot creates these two very different effects depends on the slots angle to the wings surface.

To aid the airflow, you need a slot blowing nearly inline with the surface and airflow. Known as Tangential flow, this flat entry angle creates a relatively wide slot when viewed externally.

To stall the airflow, you need a slot blowing at near right angles to the surface. This creates a narrow slot when viewed externally.

Looking at what you need to aid or stall the airflow also requires different placement of the slot.

To aid the airflow, you would inject the flow from the slot in an area downstream on the wings surface where the boundary has slowed and thickened. On a front wing this would arguably be somewhere on the flap towards its trailing edge.

To stall a wing, you want to upset the airflow where it’s moving quite fast, for a front wing it would be placed towards the leading edge of the wing. Last year with F-ducts we saw the stalling slots initially placed on the flap, until Renault placed theirs on the main plane for a better stalling effect.

This analysis suggests the narrow slot towards the leading of the front wing is for stalling not aiding the airflow.

Why stall the wing?

However, while we have got this far in reverse engineering the Mercedes front wing. We now need to work out what the benefit of stalling the front wing is. When stalling aerodynamics there are two possible benefits. Reducing drag for more top speed or reducing downforce.

Drag Reduction

For a front wing the drag loss wouldn’t be that beneficial on top speed. Sitting within the frontal area of the cars silhouette the front wing has very little form drag. However, induced drag from vortices produce particularly at the outboard ends is a factor, but far less than with rear wings. With teams increasingly bending their wings down at speed to gain greater downforce, they are creating most of the load towards the wing tips. By making the wing more aggressive at its outer ends, means that more vortices will be produced and sent around the front tyre. This flow structure creates drag and stalling the wing, especially near the tips would reduce this drag and boost top speed. Martin Whitmarsh was quoted in the AMuS article as suggesting a 5/8kph gain from stalling the front wing.

Drag is induced by the vortices created at the wing tips

With the front wing stalled, some of the energy it robs the airflow can pass towards the underfloor, increasing the pressure at its leading edge, forcing more flow under the floor for more downforce. With more downforce from the underbody, a smaller rear wing can be raced, which also creates less drag for more top speed.

Aero Balance

But that may not be the greater goal of stalling the front wing. Instead the aim may be managing the balance of the car through out its speed range. This would be done by the loss of downforce altering the cars Centre of Pressure.

Firstly, let’s review what the front wing does for the cars dynamics at different speeds. An f1 cars downforce is produced largely by the front wing, rear wing and the floor. With the front and rear wings being the main tuning elements. By tuning the front and rear downforce you alter the cars Centre of Pressure.

Centre of Pressure (CofP) is the balance of downforce at the front and rear axles. As such it’s analogous to being the aerodynamic equivalent of Longitudinal CofG (balance of mass between the axles). CofP is also known as termed as aero balance.

Typically the CofP position closely matches that the CofG. Starting from around 1-2% behind the CofG, then as the car gains speed the car gets lower making the front wing and diffuser work better. Fairly soon the stepped bottom\plank choke flow into part of the diffuser, this robs the diffuser of some downforce. While as the front wing gets closer to the track, it works in ground effect to create even more downforce. The combined effect of the loss of some rear downforce and gain in front downforce is that the CofP moves further forwards.

Such is the potential of the front wing and the near equal tyre sizes front to rear; an F1 car is largely limited on corner entry by the rear grip available. In low to mid speed turns the car needs a slight rear bias to the CofP, this prevents the car suffering corner entry oversteer. Where the car wants to spin as it approaches the apex. Too much front wing in these corners will make the car too pointy and hinder laptimes.

In faster turns the front wing can lead the car. The drivers turn in gentler to fast turns, which creates less lateral acceleration at the rear axle. So it’s rare for the rear to step out on turn-in to fast corners. Thus, at higher speeds you can have a CofP biased towards neutral or the front. Last year with the adjustable front flap, (rather than used for the overtaking balance adjustment for which it was designed) teams would use alter the front flap angle into a fast turn.

So typically you wouldn’t want to shed front downforce for fast turns, by stalling the front wing. Stalling the front wing will reduce front downforce and drive the CofP rearwards, robbing the driver of front axle load just when he needs it.

But, the move towards a rear biased high speed set up could be a response to other problems with the chassis. We knew the 2010 Mercedes W01 suffered understeer and Michael Schumacher didn’t like that facet of its handling, even though Nico Rosberg could cope with it. Perhaps Schumacher’s style of being aggressive on initial turn in, helps the car to rotate into turns more to gain speed through slow\medium speed corners. This tendency corner entry oversteer wasn’t present in the 2010 chassis.

The 2011 W02 is shorter and designed to rotate better, it certainly isn’t a natural understeer. We can suggest this forwards bias, as a possible reason for the car being hard on its rear tyres.

So if the W02 has a forward biased aero balance, this would move the car closer towards corner entry oversteer. We’ve also seen the mid season wing upgrade displays some flexibility, as with many teams front wings. This would have the effect of moving the front wing in yet closer proximity to the track and create even more front downforce at higher speeds.

So with the W02, as speed increases and the CofP moves forwards. Now the corner entry oversteer create a danger of high speed spins, the team need to calm the chassis down a little. So when the wing stalls, the CofP moves rearwards and gives the drivers more confidence with a little understeer. In Michaels case his naturally aggressive turn in is tolerated and as we’ve seen Rosberg can cope with understeer. So both drivers benefit. This might also save the tyres from slip in high speed turns, which could be detrimental to the tyres grip.

Front Ride Height

Another possibility with the stalling front wing is that it’s allowing an opportunity to play with the linearity of the cars ride height. In particular the proximity of the splitter to the ground at different speeds.

As has been much discussed, the front wing needs to run as low as possible to create downforce. To achieve this teams run as lower front ride height as possible. The limitation of a low front wing ride height is the front splitter grounding, this becomes an increasing problem as speed increases and the aero load builds up and compresses the front suspension. So at the ‘End of the Straight’ (EOS) at very high speed the car is at its lowest and splitter is grounding. This forces the car to have a higher ride height, to keep the plank from wearing away in the EOS condition. Thus at lower speeds the front ride height is correspondingly higher, compromising the potential of the wing.

If Mercedes stall the front wing as the car reaches top speed, hence above the speed of any corner on the track. Then when the wing stalls, the load on the front axle will suddenly decrease and the front ride height will increase. Effectively the ride height\speed map is no longer linear. Ride height will decrease linearly at lower speeds, then above the speed of the circuit’s fastest corner, the wing stalls and ride height increases.

What this allows the race engineers to do is shift the ‘ride height curve’ down the map for a lower initial (static) ride height. Knowing that the splitter will not ground in the end of straight condition. Therefore with the unstalled wing having a lower ride height, more downforce can be generated. When the wing is stalled the lack of downforce is less consequential as the car is on the straight. Plus there may still be the small boost in top speed from the lack of induced drag from the stalled wing.

One other potential of such a solution is the front wing grounding. We have seen the midseason version of the Mercedes front wing ground quite easily in some turns this year. So as with splitter ride height, endplate ride height at top speed may become the limiting factor in benefiting from the wing flexing at lower speeds. Stalling the wing on the straight will see the load on the wing decrease and the wing will naturally flex upwards. Giving the opportunity to flex more at slow speeds and have the stall prevent grounding on the straight.

Summary

Looking at the options listed above, I would definitely say the cars wing is stalling. with little to be gained from drag reduction the stalline is most likley to create another effect on the chassis.

In comparison to the manipulation of the CofP to resolve handling problems, the speed sensitive ride height control would be a more likely purpose of the stalling wing. Perhaps more importantly this would be a universal solution, one that other teams could legally adopt in preference to flexible splitters or excessive rear ride height to achieve lower front ride heights.

Legality

So if we now accept that this theory is how the might wing work, we need to look at the legality and construction of the set up. Firstly a passive system that involves no moving parts or driver intervention is legal. Secondly the rules on the closed sections forming the front wing are much freer than those applied to the rear wing. So slots can be legally made across the side spans of the front wing. Clearly it would be legal in both of these respects, that the stalling slot can be made to blow at certain speeds.

The biggest issue is with the nose hole itself. This is covered in the rules and is allowed for the purposes of driver cooling. This being worded into the nose cone regulations for 2009 to prevent Ferrari style slotted noses. We know the nose hole is used to blow the front wing for several reasons. Firstly Mercedes do have the nose hole, but rarely use it, instead the duct moulded into the access panels atop the chassis are normally used for driver cooling. Most of the time the nose hole is sealed up with clear tape.

But one crucial picture in the AMuS gallery accompanying their article, was of the car with the nose removed, showing a black carbon fibre cover going over the front bulkhead. This would seal the nosecone, such that air entering the nose hole would not pass into the cockpit and instead pass down the wings support pylons. With this panel in place the nose hole cannot function as driver cooling and goes against the rules. Perhaps this set up using the nose hole was just at Suzuka for testing, as Teams are unable to do much full scale testing away from the circuit. It could be legally run in a Friday practice session, as teams are given some leeway to test parts which might otherwise be unacceptable to the scrutineers. As long as the parts aren’t run for qualifying, then apparently illegal parts can get limited Friday running.

So for 2012 the wing might gain its inlet from another position. At Suzuka, the use of the nose hole might have been a good way to disguise the system when it was tested.

I have to thank the many people who aided me in my countless questions on this design. Thanks for your patience.